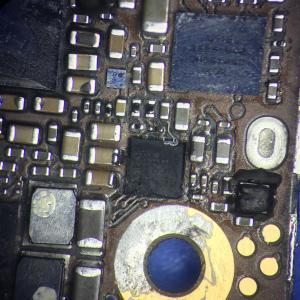

So what is micro soldering? Micro soldering is the act of soldering components so small that they can only be seen through a microscope. These small components usually consist of resistors, capacitors, inductors, connectors, diodes, transistors, microchips, etc. They fit all around a logic board with multiple layers into a teeny tiny little space and produce things like cell phones and tablets and even little computers.

With devices getting smaller and smaller and more and more expensive, sometimes fixing these devices is more beneficial than replacing them. Devices like Amazon’s Kindle Fire that sometimes cost less than $50 are usually not worth the time to fix, but iPhones and iPads that cost up to $1,000 with a broken $2 chip or connector makes sense to fix instead of buying a new one.

Also, Apple does not offer micro soldering as a repair option. They have aggressive upgrade programs, almost always recommending that customers upgrade to a new phone or tablet instead of repairing them. Most of the times, these micro soldering repairs are easily repairable with the proper tools and equipment.

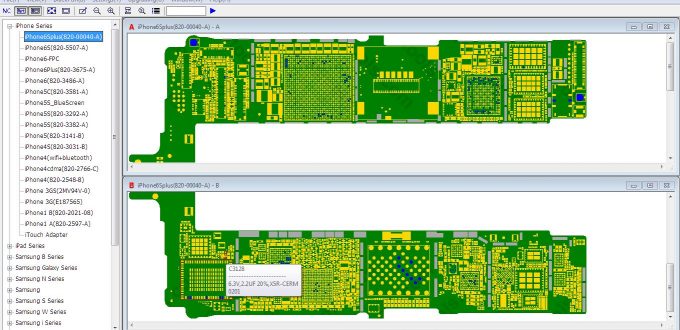

Let’s look at an iphone logic board zoomed in about 200x:

Now imagine trying to place a small bead of solder on one of those small components. Nearly impossible without the proper micro soldering tools and equipment, like a microscope, hot air rework station and a soldering station. Also required are the proper parts, supplies, and components.

Gone are the days of big CRT TVs and VHS recorders with many moving parts. These days, devices fit in your pocket and there are zero moving parts inside of the device.

Follow us here and learn all the tips and tricks of micro soldering. Request a quote to let us fix your device!